Retrofit of a press

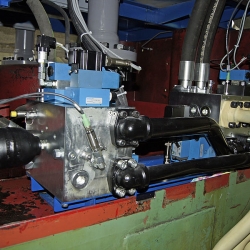

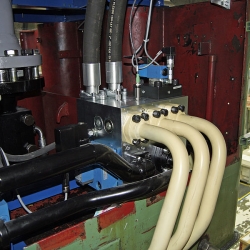

An existing pressing plant has been retrofitted in hydraulics by using the latest technologies.

Our technical project team has implemented an innovative state-of-the-art safety control block for this press.

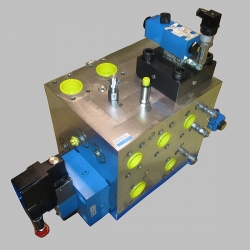

The safety manifold block is equipped with the following functions:

- free fall with proportional valve

- differential cylinder

- proportional control of the pressing pressure

- differential switching sytem (regenerative circuit)

- direction valves as switching, proportional or control valve

- integration of an accumulator

- setup mode

- leak oil free on rod side

- control oil supply for valves and pumps

- load sensing

Versions:

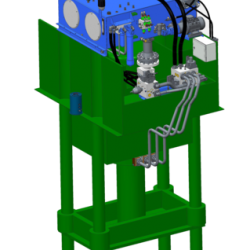

- presses with top piston design

- possible nominal sizes NG06 - NG63

- flow rates up to 2500 L/Min.

- operating pressure up to 315/350 bar

- integrated safety functions

- comprehensive safety concept

- additional functions as to your request

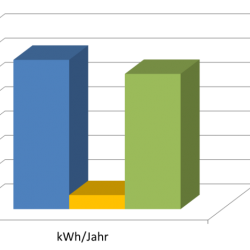

On the basis of measurements done after the commissioning, an energy and cost-to-energy ratio was compiled, in comparison with the old and the new plant. High savings of energy and costs can be achieved after implementing the new system.

The manifold block is combined with a variable speed Eaton pump and an Eaton frequency converter.

Thanks to this innovative concept, a large saving in energy consumption can be achieved. The applied safety technology meets the current safety requirements.

A detailed documentation of the system and safety is given to the customer.

The schematic diagram has been compiled according to the following guidelines and standards:

EN 693 Machine tools - Safety - Hydraulic presses

EN 289 Plastics and rubber machines - Compression moulding machines and transfer moulding machines - Safety requirements

Facts

Place: Switzerland

Date: 2017

Scope of delivery:

- Safety manifold blocks

- Hydraulic power unit

- Validation

- Safety engineering concept

- Re-Design

- Energy consumption and cost comparison

- Engineering

- Systemintegration